I wasn't going to post this for another week or two, but reading the other thread about spring vs. mild steel made me want to jump the gun a bit.

So I have been experimenting with various heat treatment recipes for spring steel in order to decide which recipe would produce the best and most reliable results for production use with my armour.

After subjecting a whole bunch of test pieces to all sorts of abuse in my shop I made 4 test plates and handed them to one of my self-described "gun-nut" students (the guy has more firearms than I do hammers) with instructions to shoot them with "old guns" and to report back to me.

The results of this very unscientific test are as follows.

Hardening process: Pieces were heated to approx 1550 degrees F and immediately quenched in canola oil (vegetable oil). Anecdotaly, veggie oil seems to give a quench somewhere between that of transmission fluid and water. I have chosen to use it in my shop because the transmission fluid made the shop stink to high heaven and tastes like it would kill me slowly. The canola oil smells like french fries and doesn't smoke nearly as much.

All pieces are approx 6"x6" and were cold dished to a depth of approx 2".

Test piece A: 16 gauge cold rolled mild steel. No heat-treatment

Test piece B: .062" 1050 Steel. Hardened and then tempered at 650 degrees F for 30 minutes and then air cooled.

Test piece C: .062" 1050 steel. Hardened and then tempered at 600 degrees F for 30 minutes and then air cooled.

Test piece D: .062" 1050 steel. Hardened and then tempered at 550 degrees F for 30 minutes and then air cooled.

All 4 test pieces were shot twice at close range while braced against the wall of a sand pit.

First with a .32 caliber black powder dueling pistol.

Second with a .58 caliber Civil-war era musket firing a 200 grain round lead ball.

Exhibit A:

Surprisingly, the very low powered .32 didn't even penetrate the mild steel sample. However, as expected the musket blew a large hole clear through. Moderate deformation of the plate, steel on the rear side was very jagged and showed many tears.

Exhibit B:

The softest of the spring steel plates fared better than the mild but not as significantly as I expected. The .32 created a minor dent while the .58 musket round did achieve penetration. The steel deformed significantly and actually tore as the musket ball deflected off from its initial impact point. No cracks formed other than the tear.

Exhibit C:

Will be the recipe I use for all of my armour methinks

The plate amazingly survived both gunshots. The .32 shattered on impact with almost no deformation of the plate. The .58 musket ball massively deformed the plate but did not achieve any penetration.

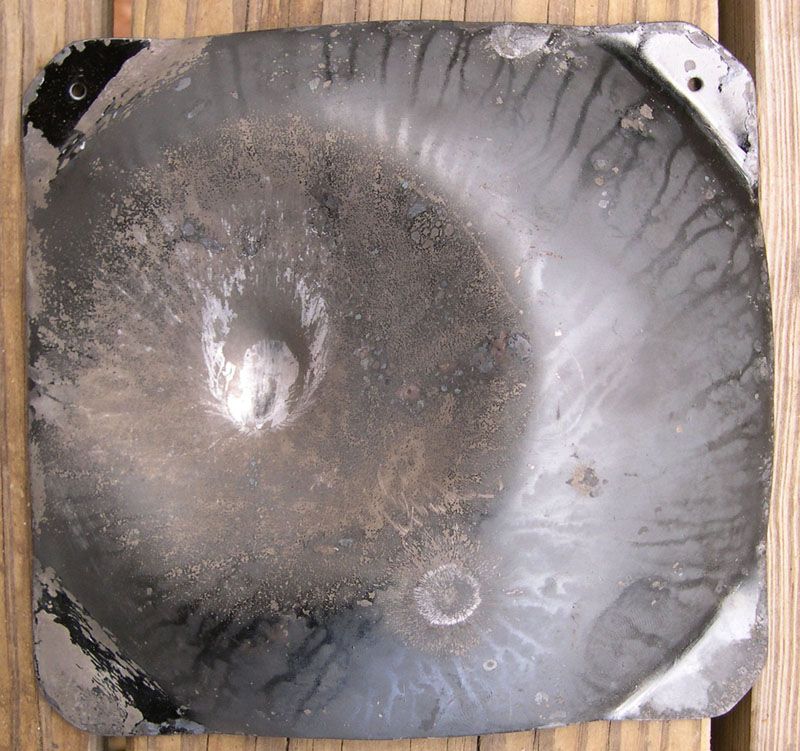

Exhibit D:

The hardest of the test pieces, which I expected to perform the best actually failed rather catastrophically. While the .32 had no notable effect, the .58 ball nearly destroyed the plate. This may be due in part to the .58 ball impact being fairly off-center compared to the other test pieces. What little was left of the .58 ball did achieve some limited penetration after some deflection but the hardness of the plate resulted in multiple fractures and cracks emanating from the point of impact.

The rear of the plate is extremely sharp and jagged and overall there is also massive deformation.

These results are fairly consistent with what I acheived in my hammer-abuse tests. Pieces tempered under 600 degrees were extremely stubborn to deform but would begin to crack under repeated blows in the same spot. 600-625 degrees appears to yield IMO the best balance of strength and durability for armour applications. Please note for anyone attempting to replicate, the choice of quenching medium WILL affect the ideal tempering temperature to achieve the same balance.

Thats all for the moment from Winter Tree Craft's R&D department. I hope you all enjoy the results of our rather unscientific test

Edit: To update links