Page 1 of 1

Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 12:09 am

by Tom B.

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 3:00 am

by Gustovic

Ashtonishing...

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 9:54 am

by wcallen

It is always fun to see other people build armour. It is always similar, but just a little different at the same time.

I am not sure how much the audience got out of the hammer demonstration. Distance and a complete lack of background probably ended up with the audience learning "it takes a long time, and boy, he hits it a lot." I guess that is something.

I need some mail in my demo suits. Hmm..... I wonder what might be happening on those mail sleeves?

Wade

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 10:24 am

by Gerhard von Liebau

"I wonder what might be happening on those mail sleeves?"

What do you mean here, Wade?

Tom, thanks for sharing the videos, but only a half-hearted thanks this morning. I wound up watching them until nearly midnight last night and I'm as tired as hell now! :p

-Gerhard

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 10:29 am

by wcallen

Gerhard von Liebau wrote:"I wonder what might be happening on those mail sleeves?"

What do you mean here, Wade?

Tom, thanks for sharing the videos, but only a half-hearted thanks this morning. I wound up watching them until nearly midnight last night and I'm as tired as hell now! :p

-Gerhard

The effort to get Ice to have some decently tailored mail sleeves made.

I don't see any current status on that.

Wade

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 10:46 am

by Mac

wcallen wrote:

The effort to get Ice to have some decently tailored mail sleeves made.

I don't see any current status on that.

Wade

Uh...That would be because I'm a slacker.

Mac

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 10:53 am

by wcallen

Mac wrote:wcallen wrote:

The effort to get Ice to have some decently tailored mail sleeves made.

I don't see any current status on that.

Wade

Uh...That would be because I'm a slacker.

Mac

Not possible. I refuse to accept that.

I will blame it on no one actually signing up to buy the things. Or something else.

Wade

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 11:33 am

by Ken Mondschein

Cooking with Jeff! We need to get him his own PBS show...

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 12:22 pm

by Jan van Nyenrode

Ken,

Second, would be nice to have a show where you can watch people armouring, and see every stroke, while they are taling about their trade. Would be as relaxing as watching Bob Ross paint, but more usefull for me

.

Cheers,

Jan

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 1:30 pm

by Johann ColdIron

wcallen wrote:Mac wrote:wcallen wrote:

The effort to get Ice to have some decently tailored mail sleeves made.

I don't see any current status on that.

Wade

Uh...That would be because I'm a slacker.

Mac

Not possible. I refuse to accept that.

I will blame it on no one actually signing up to buy the things. Or something else.

Wade

Heck, I'll jump on the grenade if it will goad the process.

I will need a pair, ultimately. Ones that work with human arms would be a plus...

I'd imagine that this is just one of MANY irons Mac has in the fire(s).

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 3:06 pm

by Pitbull Armory

Thank you for the links Tom B, Hal PM inc now.

ty

Pb

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 3:42 pm

by Tom B.

wcallen wrote:Mac wrote:wcallen wrote:

The effort to get Ice to have some decently tailored mail sleeves made.

I don't see any current status on that.

Wade

Uh...That would be because I'm a slacker.

Mac

Not possible. I refuse to accept that.

I will blame it on no one actually signing up to buy the things. Or something else.

Wade

We had verbal commitment from more than enough for Ice's minimum order of 6.

Ice was not going to make the pre-order available on his site until he had a price from the supplier in India.

The supplier in India was not going to give a price until they had seen the exemplar.

Tom

Re: Jeff Wasson videos Dressing in Steel

Posted: Tue Mar 12, 2013 5:01 pm

by wcallen

Tom B. wrote:wcallen wrote:Mac wrote:wcallen wrote:

The effort to get Ice to have some decently tailored mail sleeves made.

I don't see any current status on that.

Wade

Uh...That would be because I'm a slacker.

Mac

Not possible. I refuse to accept that.

I will blame it on no one actually signing up to buy the things. Or something else.

Wade

We had verbal commitment from more than enough for Ice's minimum order of 6.

Ice was not going to make the pre-order available on his site until he had a price from the supplier in India.

The supplier in India was not going to give a price until they had seen the exemplar.

Tom

Shhh.

Repeat after me - "It is not Mac's fault......"

Facts have little to do with this.

Hmm. If Mac has a sleeve in almost usable state, maybe he will bring it to Baltimore and we can play with it. That would be fun. I would like to see the quality of the raw material and what size the current guesstimate is.

Now back to admiring Jeff's videos?

Wade

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 13, 2013 3:55 am

by Aussie Yeoman

If they need more to commit to buying tailored mail sleeves, I will buy some too. Depending on the price.

Back to the videos. I've only watched half the first one, and feel I could watch it all day, just taking it in.

I notice he uses square and round faced hammers for different tasks. Like a square faced hammer for pounding out the rerebrace. How much does hammer face shape matter for this kind of thing? By 'this kind of thing' I mean armouring. I know Mac uses a round faced, domed hammer for raising, while almost everyone else seems to use a domed rectangular faced hammer.

I'm not sure I'm coming across completely clearly, but we'll see, eh?

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 13, 2013 6:36 am

by Uilliam Le Syngur Ingelrie

I am wondering what kind of stone he is using for the little forge? How can he grab the top stone with bare hands?

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 13, 2013 6:56 am

by Kindyr

I'm fascinated by the elbow stake. I don't think I've seen any other armorer use something similar. Seems like it would also work really well for helms.

Uilliam - I think the top stone is a carved refractory brick, the same as the two bottom bricks. They would be highly insulative, so the edge away from the torch should be cool to the touch.

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 13, 2013 7:12 am

by wcallen

Kindyr wrote:I'm fascinated by the elbow stake. I don't think I've seen any other armorer use something similar. Seems like it would also work really well for helms.

Knut had a knee stake. That would have been late 70's, to about 80.

Hmm. Aaron and I had one. That was in the early 80's I think.

Tom has one.

I think I remember Mac having a shaped stake, not a full elbow, but enough of the shape to allow for planishing (I could be wrong here).

We also had a knee stake.

We even had a helmet half male and female.

Wade

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 13, 2013 10:17 pm

by Geoffrey the Younger

Tom, thanks for posting this. -- I knew it was being taped, but the camera feed was going to a projection so the audience could see what I was doing up close. I didn't think it would end up on Youtube. --a pleasant surprise!

There were two other sections with Dirk talking about armour and showing images. Unfortunately that didn't get recorded.

On the hammers: The hammer with a square head is flat and is only used on the outside of curved pieces over a ball stake. the other side of that hammer has a round head with a slight convex curve that is perfect for hammering flat plates and similar planishing work. I used it to hammer out the rerebrace in the video. The other one that looked sort of squareish was the one with the longer head that I can get into cuisse, and greave plates to planish and shape with. It is really handy. I made it myself. I have about 8-10 hammers that I use on a regular basis. They vary in shape and in weight. Yes, you can raise with just a round hammer, it doesn't need to be rectangular. You don't want any sharp edges that might imprint themselves onto the surface you are raising.

Yes, the firebrick is really insulative. One side can be glowing and the other is cool enough to pick up. I really probably shouldn't have picked it up with my bare hand though! Usually I wear a glove. Those firebricks are really handy for building a propane forge out of an ordinary mapp gas tank. I use these "mini forges" in a metalworking class I teach at SVA. The bricks trap the heat and allow it to get really hot.

The Forms; I have made quite a few over the years out of 1/4" plate and I find them really handy. I use both inside and outside forms, and will go back and forth between them. So I have a couple different elbow stakes, Knee stakes, helmet stakes. Mac turned me on to making these forms out of 1/4" steel. You can use them Hot -- which is the way to go if you want to really shape something. I like welding 3/4" square stock onto them so they fit in the vice or the hardie hole of the anvil. I also have a T-stake with a hardie hole in the end so I can change out the forms rather than make new T-stakes all the time.

--Jeff Wasson

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 13, 2013 11:52 pm

by Aussie Yeoman

Thanks for that clarification Jeff.

I just finished watching all of the first part. I was quite disappointed to see you told time was up! Could have watched it all day.

Perhaps the most surprising thing I saw was how quickly you knocked that rolled edge out. Does it normally progress that fast? It was interesting to see you went from straight to 90 degrees in one or two passes, while in Eric's videos he seems to take a few more passes on rolls that are not all that dissimilar in size. One thing's for sure - if I tried to roll edges that fast, they would be awfully misshapen messy things.

The forms you use, particularly the female ones...I assume you raised those in the first instance to be pretty much the right size minus the thickness of the steel of the actual component?

There's so much I would want to ask. It would become far too annoying though. I and many like me will have to make do with the most targeted questions we can think of, then hoping the rest falls out of the rest of the experts. And that we have the insight to pick up on it ourselves.

Re: Jeff Wasson videos Dressing in Steel

Posted: Thu Mar 14, 2013 7:23 am

by Tom B.

Geoffrey the Younger wrote:Tom, thanks for posting this. -- I knew it was being taped, but the camera feed was going to a projection so the audience could see what I was doing up close. I didn't think it would end up on Youtube. --a pleasant surprise!

You are welcome.

Thank you for doing the demo!

Geoffrey the Younger wrote:

There were two other sections with Dirk talking about armour and showing images. Unfortunately that didn't get recorded.

How disappointing.

At least your part had some good video.

Geoffrey the Younger wrote: Those firebricks are really handy for building a propane forge out of an ordinary mapp gas tank. I use these "mini forges" in a metalworking class I teach at SVA. The bricks trap the heat and allow it to get really hot.

So you are just using one of those little BernzOmatic MAPP gas torches unmodified?

Which tip is used,

the high intensity swirl flame?

Anything special about the shape or clearances on the "fire brick forge"?

How long does the gas last?

Ever use propane? (I know MAPP is much hotter)

Geoffrey the Younger wrote:The Forms; I have made quite a few over the years out of 1/4" plate and I find them really handy.

I assume that you just formed these hot and welded & ground to the shapes needed, right?

Thanks for doing the presentation and taking the time to come here and answer questions.

Re: Jeff Wasson videos Dressing in Steel

Posted: Thu Mar 14, 2013 9:24 am

by Gruber

I love your work Jeff! Question. May be six of one, half dozen another but, I've been preaching raising over a stake for knees ,elbows ect for ages... just because I can make the material a little thicker. By sinking I've always figured I would be stretching it thinner. Your demo is maybe half the time I take to raise. Is the amount of stretch you get negated by planishing the material back to the deepest point of the shape? Or have I fallen to armouring lore that dishing isn't as strong as raising? I usually use 18 gauge 1050, just to give you an idea of what I work in. Thanks for any input, critique, ideas you have...

My question is purely humble, I'm just looking for another point of view- anyone?

Re: Jeff Wasson videos Dressing in Steel

Posted: Thu Mar 14, 2013 2:49 pm

by Pitbull Armory

[quote="Kindyr"]I'm fascinated by the elbow stake. I don't think I've seen any other armorer use something similar. Seems like it would also work really well for helms.

Same here Kindyr, Im having Halberds make one for me as we speak, Very cool stake.

Gruber I hot sink for almost everything, I am certainly no master, but ive found that if you make it red and start at the outside, moving to the center in a circular pattern it pushes the material in towards the center and doesent thin it that much at all.

Great work Jeff, thanks for sharing Tom,

Have a good week guys

Pitbull

Re: Jeff Wasson videos Dressing in Steel

Posted: Thu Mar 14, 2013 2:54 pm

by Gruber

I've heard that too Pittbull, I think I'm too chicken to try it on a production piece.... gotta try it soon.

Re: Jeff Wasson videos Dressing in Steel

Posted: Thu Mar 14, 2013 7:45 pm

by Pitbull Armory

I should mention I use 14g for the cops and most of the stuff I sink, If you take some 12g and sink it you can mic the center when your done and check for thinning, then sell it as a shield boss or something maybe. Hey G how many of those armoring vids do you have made yet>? I want to buy a couple of them. I think you said you were going to make one on running 2 or 3 flutes together or something? It would be interesting to watch you work.

Pm me info if you get time.

Take care

Pb

Re: Jeff Wasson videos Dressing in Steel

Posted: Thu Mar 14, 2013 8:34 pm

by Gruber

Andy- pm sent

Re: Jeff Wasson videos Dressing in Steel

Posted: Fri Mar 15, 2013 7:28 pm

by scott2978

Wow... I watched the first video totally fascinated. I wish I could watch him make a full harness!

Re: Jeff Wasson videos Dressing in Steel

Posted: Sat Mar 16, 2013 2:26 pm

by Geoffrey the Younger

Rolling edges does happen pretty fast. I have done them so often I feel comfortable working quickly. If you are learning how to do this stuff, don't try and speed up the process -- work on good form. Most metalworking forming happens in manageble steps or stages. As you get confident you know where you can push the limit.

Everyone has different methods for working and making things. I have tried different stuff over the years and have fallen into using certain techniques because they work for me. Yes raising thickens the metal and dishing thins it -- I use the different techniques where they give the best results. Most of my elbow cops and knee cops, If they are really deep or shapely I make from cones that are welded and than forged down on one of those elbow type stakes. I also have a knee stake as well. This keeps the metal the same thickness or makes it thicker where the point is raised down. I would rather do this than raise since the raising is time consuming for me. For breastplates I usually make a pattern that is a cone and forge down the point. I'll dish things like shoulder cops if they are not to deep. I dish elbows and knees reluctantly -- because I know I am making it thinner; If I do I always use a thicker metal -- 18 ga or 16ga.

I don't know how medieval armourers shaped there plates. I don't think anyone truly knows. I will say that the plates they used were much different than the consistent thickness of the material that we have to work with nowadays. Medieval plates were hammered using a water driven power hammer or sledge and could vary in thickness throughout. I suspect that they used this to their advantage to make the plates thicker in the centers and thinner at the edges. You could sink or stretch a plate like this and it would still have enough thickness to meet tolerances. So they took advantage of the irregular thickness -- putting it in the front of the breastplate or the front of the helmet, visor ect.. I have often been annoyed that I can't capture this thickness.

For greaves, and shaped vambraces I use a combination of dishing, raising and planishing to get the shape, usually always hot. I also have special forms that allow me to create volume and then refine it and smooth out the metal. I use a propane forge for most of my heating -- A much larger version of the forge in the video.

The forge in the video is made of just a standard mapp gas tank with the trigger burner. I made a special stand to hold it in the right angle. The firebricks are arranged to take the heat from the flame and contain it around whatever you are heating. I picked up on this setup from a book called the $50 knife shop. I have adopted it to heat plate for demos like this and other places where a real forge just wouldn't work. One time I put a bunch of these torches together to get lots of heat and melted bronze and also heat up and bent a large pipe!

Cheers,

--Jeff

Re: Jeff Wasson videos Dressing in Steel

Posted: Sat Mar 16, 2013 8:55 pm

by Aussie Yeoman

Jeff, every time you give me an answer, it is a seed sown in fertile ground that sprouts more questions.

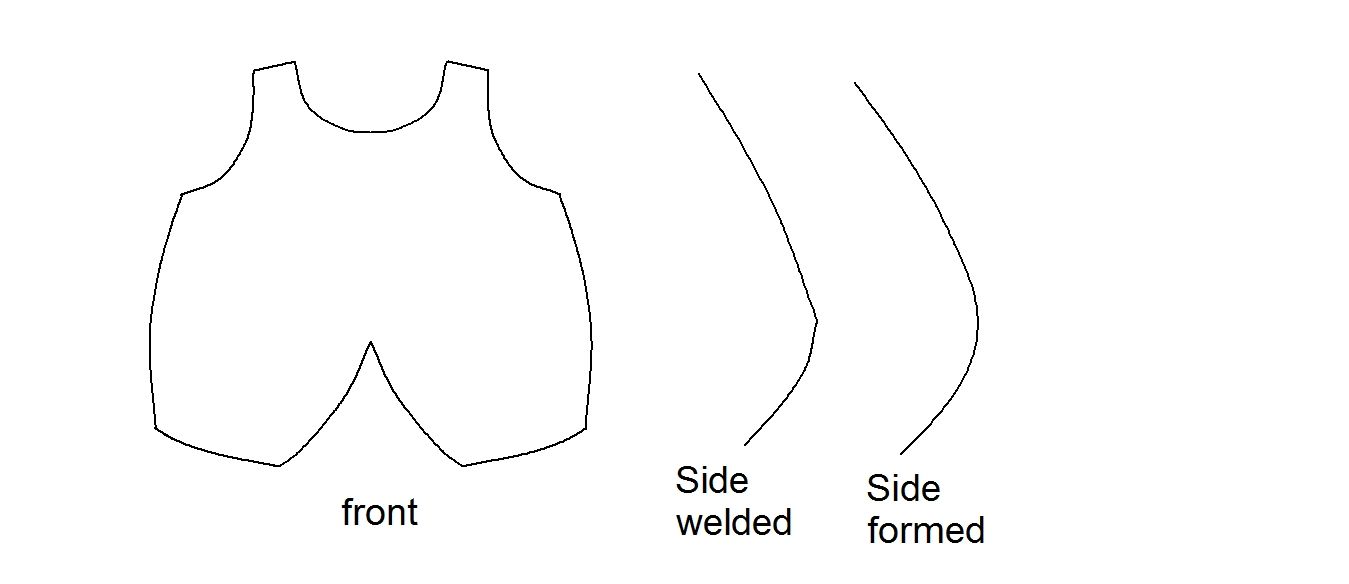

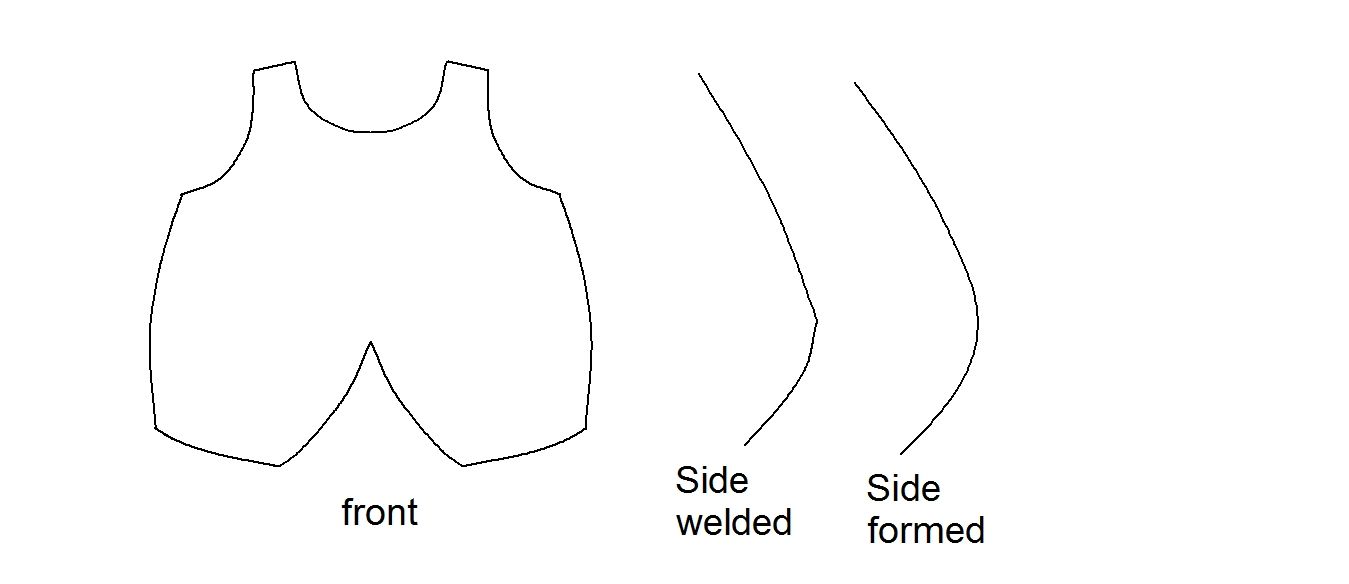

When you say your breastplates are a cone, I picture more or less a regular breastplate pattern but with a split from the lower edge up to the deepest part of the finished breast or maybe a little higher, and the bottom spread out. Kind of like this:

Is that what you mean? I had recently been wondering about such a strategy, but using multiple splits, but narrower, so that when closed and welded they more closely approximate the wasp-waist effect seen in Italian armours from the 15thC at the welded stage and thus not need to move as much steel in subsequent stages.

Would you use a welded cone even for things like Milanese and Gothic knees which are quite generously round? I must say, the possibilities of squashing blocky shapes welded from panels and cones are tremendous, such as these two projects:

viewtopic.php?f=1&t=158178

viewtopic.php?f=1&t=159650

Thanks for sharing with us. It is most heartily appreciated.

Re: Jeff Wasson videos Dressing in Steel

Posted: Sat Mar 16, 2013 10:43 pm

by coreythompsonhm

Aussie, i cant get the link right now because Im on my phone, but william hurt has a peascod bp pattern on the pattern archive with the same split like you drew up to form the deep portion

Re: Jeff Wasson videos Dressing in Steel

Posted: Wed Mar 20, 2013 10:09 am

by Pitbull Armory

Hi Jeff, I was alarmed at the speed and the power of the hammer blows you closed that roll with in the video, As you did it I was thinking,,,, that roll is gonna be lumpy! But it turned out great nice work, I can close em fast but not with hammer blows that hard. Nice work on the vid and the armor,

Take care

Pitbull