viewtopic.php?f=1&t=170292

I decided I would have a go at designing a knee to play around with articulating on paper, and get something working right in the planning stages before (one day) transferring to steel.

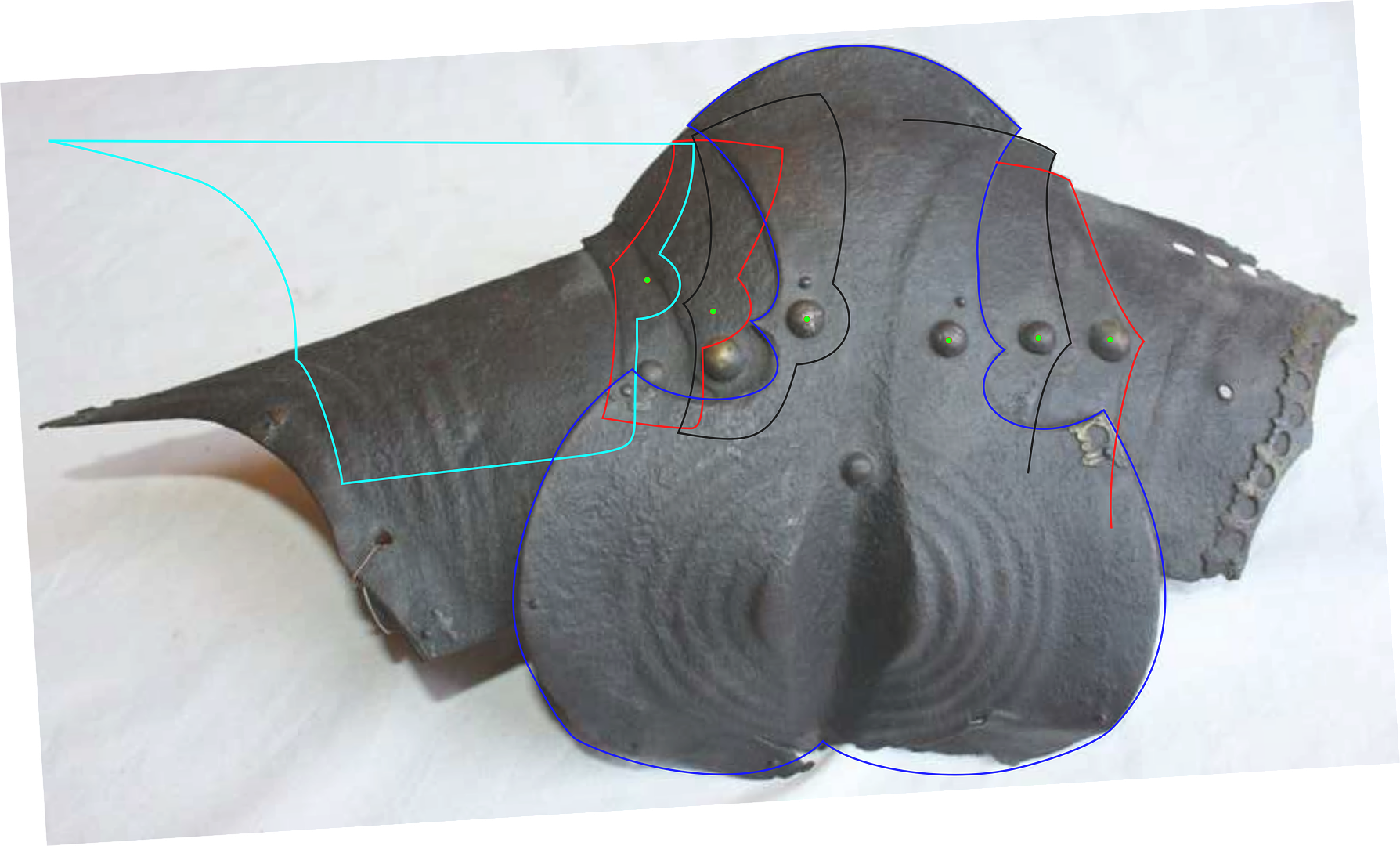

The example is the knee of this statue:

My first supposition was that the cop is too shallow, so in the sketching I made it deeper. I had originally made the proportions of the height (height of the cop to height of the point of articulation) of the cop fairly similar to that in this picture. However as I played around with where the articulation points needed to be in order to move the lames smoothly and with minimal gap through the flexion/extension, the rivets got a lot closer together.

As a result the cop tapers in height a lot more in my sketch than in the sculpture. At the moment I'm not fussed by the wing.

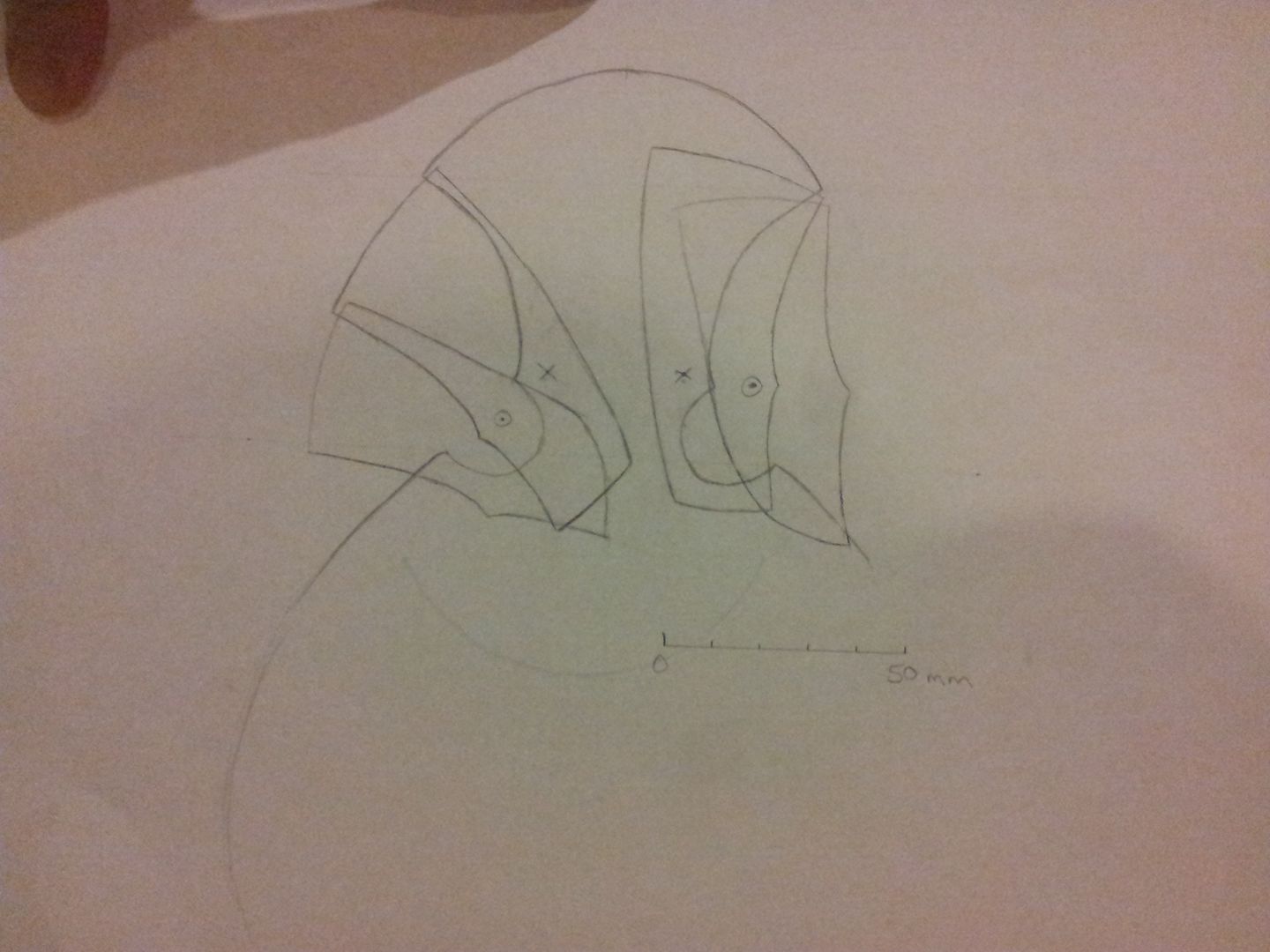

It took about half an hour. I used baking paper to play around with the lames. It's very see-through, takes pencil well and more importantly, pencil erases off it exceptionally cleanly.

I ended up with this:

I hope you can make sense of all the gray lines.

When I first finished I was quite pleased with it because the joint, when flexed, was not 'Michelin Man-like', and there was little gapping through the whole range of motion.

Then it struck me that the distance between the rivets and the second lames when extended, might not be enough to accommodate the patella when the rivets are sitting around the organic joint of the knee.

I guess I should have quick sketched the cop over a photo of my knee to see what the proportions should actually have been. But then again I might have just snuck in with a win on this one.

I'll now throw to the audience to see what others have to say.

Goll 2845

Goll 2845 Goll 3020

Goll 3020