Last night I spent the hours between 8 and 11 sewing the gable gores together, but I neglected to take any pics.

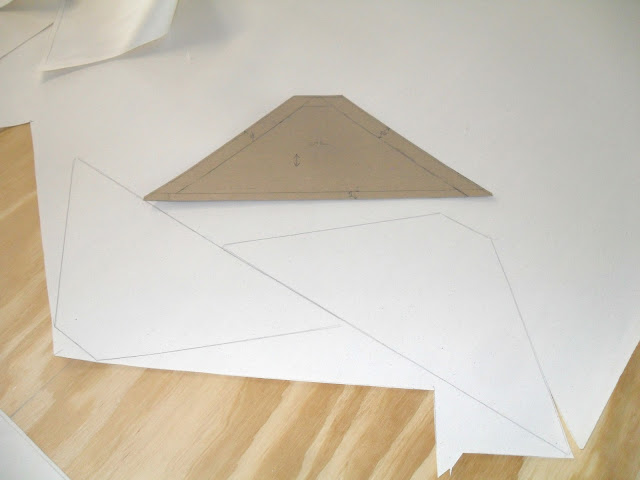

As I suspected, my template for the triangular top piece was off by the time I was done sewing the gores. It was not off by as much as I had feared, but it was worth making a new template anyways. This time, I just used cardboard, and made it include the seam allowances

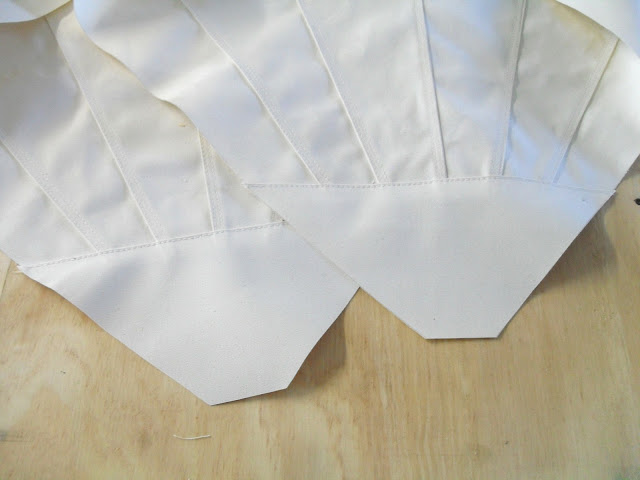

This is what the tops of the gables look like with the first layer of the triangular piece sewn in place.

For the second layer, I used the same template, but added one inch to the bottom.

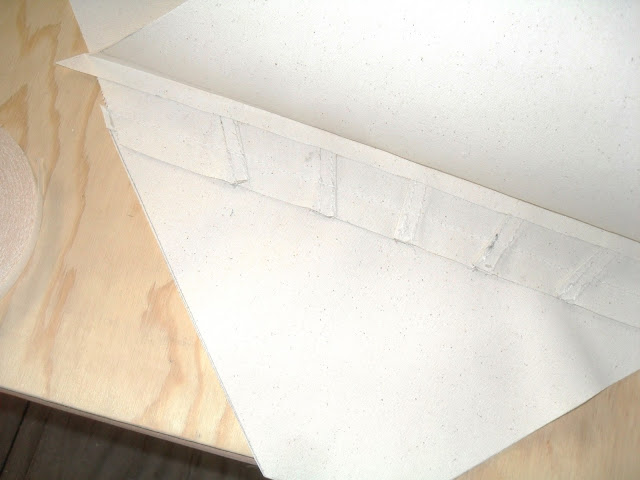

Here is what the back side looked like while I was attaching the second layer. In the photo, it is held in place with polyester basting tape.

Both layers are in place here, and I have stitched around the edges to help control the layers when it comes time to flat-fell the gables to the rest of the canopy. Note that the triangles have an extra 1/8" of seam allowance. This will give me extra material for the bulkiest part of the seam.

That was the sexiest part of the construction, but it had to be done first. Now I will use the completed gables to figure out the lengths of the canopy panels. I hope to get those cut out this afternoon and sewn together tonight.

Mac