Traditional Armor Finishing Processes

Moderator: Glen K

Re: Traditional Armor Finishing Processes

From Roland Warzecha in DE: There is an ExArch page for Florian Messner's project https://exarc.net/issue-2020-1/at/reconstructing-medieval-polishing-bench He says he was not able to obtain emery, didn't we find a few sources for emery blocks and powder online?

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

Celtic Web Merchant in the Netherlands sells powdered pumice https://www.celticwebmerchant.com/en/pu ... asive.html I don't recall powdered pumice being used to polish metal, but it might be worth a try. Their shipping is quick and not crazy expensive for pandemic-times.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

-

Chris Flagstad

- Archive Member

- Posts: 72

- Joined: Sat Jan 06, 2018 8:06 pm

- Location: Ramona CA

Re: Traditional Armor Finishing Processes

Kristoffer wrote: ↑Mon May 01, 2017 5:15 am This tool came up in a fb group I am a member of. Perhaps it is an decendant to the sticks. In swedish it is called a "Pansarfil". It latest use is filing car panels and such.

Does Pansarfil translate to "armor-file?"

It seems like just the right tool for the job.

https://www.youtube.com/watch?v=-NkEsJZB7oU

-

John Vernier

- Archive Member

- Posts: 232

- Joined: Mon Mar 14, 2011 5:57 pm

- Location: south central Indiana

Re: Traditional Armor Finishing Processes

I think it does translate as you say. However, these are auto body solder files. They are meant for use on body solder which is used for soldering and sculpting body panels much the same way Bondo is. The solder is much softer than steel and the files have very coarse wide teeth designed to bite the solder, and they are also made from a steel which is flexible enough to take a curve when mounted in a special holder. I don't think they would function on steel as well as normal machinists' files.Chris Flagstad wrote: ↑Fri Jun 03, 2022 8:03 pmKristoffer wrote: ↑Mon May 01, 2017 5:15 am This tool came up in a fb group I am a member of. Perhaps it is an decendant to the sticks. In swedish it is called a "Pansarfil". It latest use is filing car panels and such.

IMG_20170501_122125.jpg

Does Pansarfil translate to "armor-file?"

It seems like just the right tool for the job.

https://www.youtube.com/watch?v=-NkEsJZB7oU

Re: Traditional Armor Finishing Processes

Its probably worth mentioning that Chris Dobson is coming out with a book Beaten Black and Blue on the surface of plate armour. Whereas JAG and Wade see middling armour in the 15th century as finished with 2 or 3 polishing media leaving scratches on a bright surface, Dobson envisions a lot of deliberately applied oxide finishes on a surface which had been roughly ground to remove the hammer marks.

I liked his book on armour from Piedmont. There is some Facebook drama about which of the armours in his sample pictures are authentic.

I liked his book on armour from Piedmont. There is some Facebook drama about which of the armours in his sample pictures are authentic.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

Craig and Nathan of Arms & Armor (Minnesota) point me to this article by Jonathan Tavares, Jonathan “Arms and Armor in Ms. Fr. 640” https://edition640.makingandknowing.org ... _308_ie_19

They also have an article on Black Varnish for Armour which draws on different sources than I drew on. I need to get my big article on the surface of plate armour from 2016 published.

They also have an article on Black Varnish for Armour which draws on different sources than I drew on. I need to get my big article on the surface of plate armour from 2016 published.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

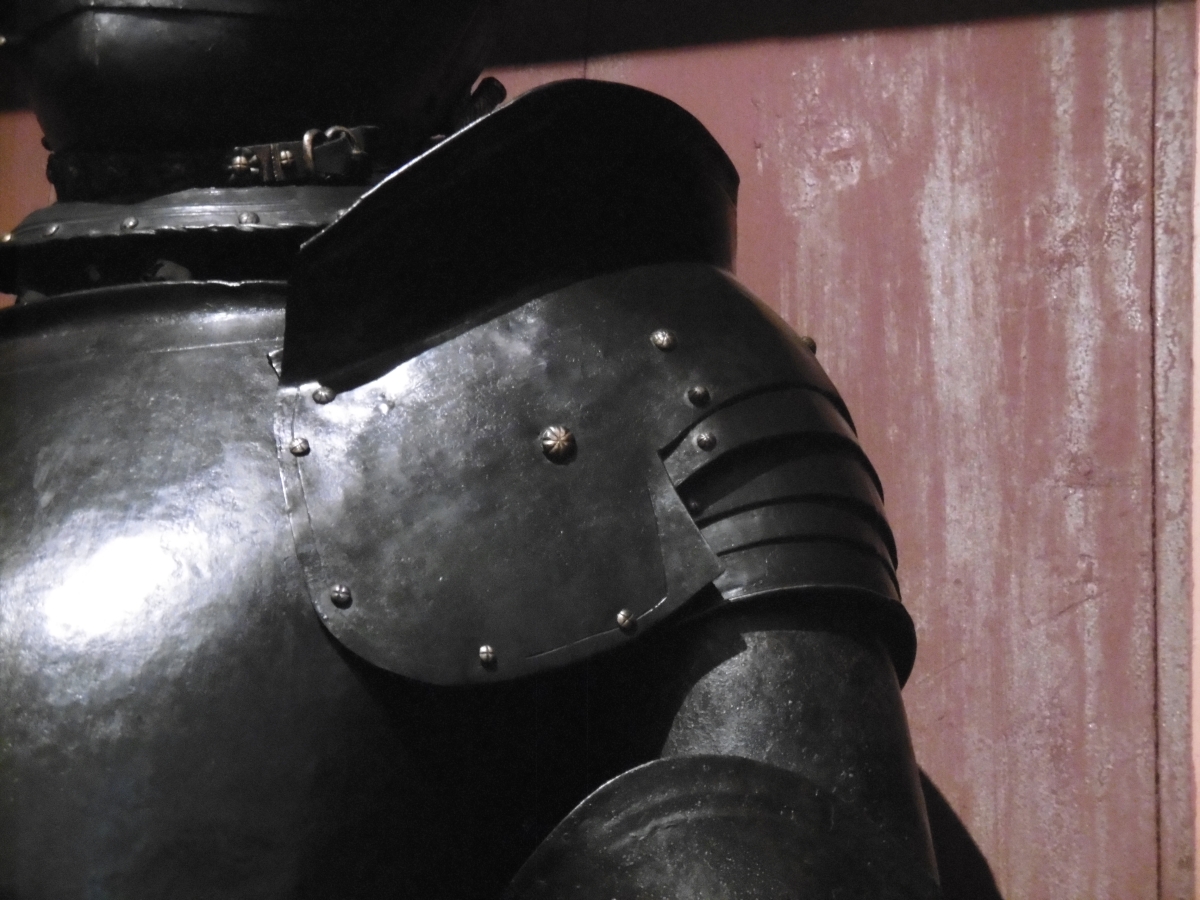

I thought it might be helpful to post three of Chris Dobson's best examples of paintings that show bright steel next to dark steel.

The Beheading of St. John the Baptist, by an unknown Catalan artist around 1450 Met. He thinks that all the grey armour and weapons is paint over silver leaf, and that the paint or varnish has flaked off one greave in the background. He thinks that thecutting edge of the falchion is bare silver without coloured overpainting.

Biagio d'Antonio, The Triumph of Camillus from around 1470/1475 National Gallery of Art, Washington DC.

Christ Mocked or The Crown of Thorns by Hieronymous Bosch, from around 1479-1516 https://commons.wikimedia.org/wiki/File ... ch_059.jpg. The head of the crossbow bolt is white steel, the gauntlet is blackened.

Its an expensive book and not everyone who is talking about it on social media has read it. I think most of us here agree that by sometime in the 15th century, there are so many detailed paintings with black armour, and so many alabaster effigies with black armour, that it must have been pretty common in some places by the middle of the 15th century.

I would say that the buckle of the soldier's dog collar is likely tinned or a low-grade copper alloy, not bare steel.

An armour for Nikolaus III. Radziwill with his "grey russet" finish is here https://www.khm.at/objektdb/detail/371403/

The Beheading of St. John the Baptist, by an unknown Catalan artist around 1450 Met. He thinks that all the grey armour and weapons is paint over silver leaf, and that the paint or varnish has flaked off one greave in the background. He thinks that thecutting edge of the falchion is bare silver without coloured overpainting.

Biagio d'Antonio, The Triumph of Camillus from around 1470/1475 National Gallery of Art, Washington DC.

Christ Mocked or The Crown of Thorns by Hieronymous Bosch, from around 1479-1516 https://commons.wikimedia.org/wiki/File ... ch_059.jpg. The head of the crossbow bolt is white steel, the gauntlet is blackened.

Its an expensive book and not everyone who is talking about it on social media has read it. I think most of us here agree that by sometime in the 15th century, there are so many detailed paintings with black armour, and so many alabaster effigies with black armour, that it must have been pretty common in some places by the middle of the 15th century.

I would say that the buckle of the soldier's dog collar is likely tinned or a low-grade copper alloy, not bare steel.

An armour for Nikolaus III. Radziwill with his "grey russet" finish is here https://www.khm.at/objektdb/detail/371403/

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

-

Len Parker

- Archive Member

- Posts: 624

- Joined: Sat Sep 25, 2010 7:47 pm

Re: Traditional Armor Finishing Processes

This https://quod.lib.umich.edu/c/cme/EEWill ... w=fulltext has a pare glovis of plate white and also a pare of glovys of plate blacke.

Re: Traditional Armor Finishing Processes

I agree, that is one of the good ones. We just don't have anything from medieval England which describes the surface of so many armours as the Archivio Datini di Prato.Len Parker wrote: ↑Sat Nov 04, 2023 8:38 am This https://quod.lib.umich.edu/c/cme/EEWill ... w=fulltext has a pare glovis of plate white and also a pare of glovys of plate blacke.

I might dig up some of the photos of medieval armour which Chris Dobson sees as having traces of an original grey oxide finish from letting it cool in air then quenching it in oil. It seems plausible that oxide finishes got more common as armourers started to quench and temper their armour (Datini started to mention tempered steel armour from Milan in the 1380s). "Just how common?" and "which oxide finishes?" is a big question.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

And here are some of the documents from seventeenth-century England which talk about the surface of armour.

Markham's Soldier's Accidence (1625) https://quod.lib.umich.edu/e/eebo/A0696 ... w=fulltext

or an English document from 1618 in ffoulkes https://archive.org/details/armourerhiscraft00ffouuoft/

Thomas Rymer's Foedera, conventiones, literæ, et cujuscunque generis acta publica ... (London, 1704) volume 19 pp. 309-316 https://archive.org/details/bim_eighteenth-century_foedera-conventiones-l_rymer-thomas_1704_19/page/315/mode/2up

Markham's Soldier's Accidence (1625) https://quod.lib.umich.edu/e/eebo/A0696 ... w=fulltext

So armour for infantry should either be russet, sanguine, or black (which resist rust) or white or milled (which do not resist rust).All this Armour is to be rather of Russet, Sang•ine or Blacke colour• then White, or Milld, for it will keepe the longer from rust.

or an English document from 1618 in ffoulkes https://archive.org/details/armourerhiscraft00ffouuoft/

or the long document on the prices of equipment for the trained bands from 1631The Footman's Armor, containing Breast, Back, Gorgett, head piece, and laces (taces ie. tassets?), with iron joints, to be colored russet, at the price of £ 1 10 s.

Thomas Rymer's Foedera, conventiones, literæ, et cujuscunque generis acta publica ... (London, 1704) volume 19 pp. 309-316 https://archive.org/details/bim_eighteenth-century_foedera-conventiones-l_rymer-thomas_1704_19/page/315/mode/2up

So russetting is a treatment for old armour which you apply after taking the armour apart (unstriking) and filing it. I don't know the current thinking on whether English Civil War russet armour was a red-brown finish applied cold, or a grey-black finish applied by slack quenching.Table: The Rates for repayring and dressing of a Horsemans Armour and Footmand Armour.

For unstriking, new fyling, russetting, new nayling, leathering, and lyning of a Cuirasiers Armour: £ i s. iii

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

A few years back Craig at the Oakeshott Institute did a talk on the finish of medieval sword blades. They have some photos of an Oakeshott type X or XI blade with traces of something similar to JAG's 'shiny between the scratches.' Photo quality is not up to Carlo P's standards since its YouTube.

https://youtube.com/watch?v=Jk8LoeQs5UQ&t=204s

https://youtube.com/watch?v=Jk8LoeQs5UQ&t=204s

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

Either Barbara G. or gaukler reminded me that early European recipes for quenching, such as Theophilius and "vom Stahl und Eisen" from 1532, focus on quenching in water. Sometimes they add secret ingredients or get the water from a special source (urine, blood) but the mixture is mostly water. Chris Dobson's theories often involve quenching in oil, and he is convinced that quenching in water can lead to rust forming under the oxide and that Mann ruined the armour from Madonna delle Grazzie by boiling it to remove 400 years of oil, dust, mouse poop, and paint.

Is there any evidence for quenching in oil in the medieval or renaissance periods?

My understanding is that water is the most aggressive quenching material and that oils tend to cool slower. I have never done any hot metalwork.

Is there any evidence for quenching in oil in the medieval or renaissance periods?

My understanding is that water is the most aggressive quenching material and that oils tend to cool slower. I have never done any hot metalwork.

Last edited by Sean M on Thu Mar 14, 2024 3:14 pm, edited 1 time in total.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

A note on Armour of the English Knight volume 3 page 8 lists armours from 1490 onwards which Capwell thinks were left basically unpolished such as the Milanese armour in Schloss Ambras (Kunsthistorisches Museum, HJRK number A 184).

An early MS with the dark shiny armour that we see in Northern Renaissance paintings is Bibliothèque d'Amiens Métropole, MS.483 Eracles from around 1440-1445. I think that was what Mac was aiming for in Toby's black armour.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

-

Mark D. Chapman

- Archive Member

- Posts: 173

- Joined: Fri Oct 31, 2003 2:01 am

- Location: USA

Re: Traditional Armor Finishing Processes

Sean, I do quite a bit of hot working and have quenched and tempered both blades and armour. You are correct water is much more aggressive than oil. For this reason the formulas for the quenchant got complicated as they added ingredients that they felt gave them a better result based on weird association of characteristics theories or just practical experience. They did not really understand the quenching process in modern terms, just the practical results they saw. Example, what a modern person would call a slack quench can produce very similar results to a full quench and proper temper.Sean M wrote: ↑Thu Feb 01, 2024 7:01 pm Either Barbara G. or gaukler reminded me that early European recipes for quenching, such as Theophilius and "vom Stahl und Eisen" from 1532, focus on quenching in water. Sometimes they add secret ingredients or get the water from a social source (urine, blood) but the mixture is mostly water. Chris Dobson's theories often involve quenching in oil, and he is convinced that quenching in water can lead to rust forming under the oxide and that Mann ruined the armour from Madonna delle Grazzie by boiling it to remove 400 years of oil, dust, mouse poop, and paint.

Is there any evidence for quenching in oil in the medieval or renaissance periods?

My understanding is that water is the most aggressive quenching material and that oils tend to cool slower. I have never done any hot metalwork.

Also I am like you I can not remember seeing period recipies for an oil quench. I will have to go looking.

Mark

Mark D. Chapman

Re: Traditional Armor Finishing Processes

Fernando Quesada Sanz the archaeologist of Iron Age Iberia takes for granted that many ancient Iberian swords, cleavers, daggers, and sheaths had blued or blackened finishes so that silver-wire inlays stood out against the dark iron. Some seem to survive with an oxide finish.

All these processes like burning horn onto steel could be fun to play with on scrap steel if you have access to a forge. We never fixed the doors to the fireplace and we don't have a wheeled firebowl or something like that.

Edit: here is Graham of GreenLeaf workshop on his oil blackening techniques https://www.youtube.com/watch?v=1APNUh5GTKA

All these processes like burning horn onto steel could be fun to play with on scrap steel if you have access to a forge. We never fixed the doors to the fireplace and we don't have a wheeled firebowl or something like that.

Edit: here is Graham of GreenLeaf workshop on his oil blackening techniques https://www.youtube.com/watch?v=1APNUh5GTKA

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

Re: Traditional Armor Finishing Processes

The 'Helm of St. Wencaslaus' in Prague currently has its surface covered with grey-black oxide https://sagy.vikingove.cz/en/on-the-ori ... as-helmet/ One recent hypothesis is that it was given the silver decoration in the late 10th century, and that it once had a mail drape which was worked into the mail cape. So this might be how it was finished after the end of its working life.

DIS MANIBUS GUILLELMI GENTIS MCLEANUM FAMILIARITER GALLERON DICTI

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410

VIR OMNIBUS ARTIBUS PERITUS

Check out Age of Datini: European Material Culture 1360-1410